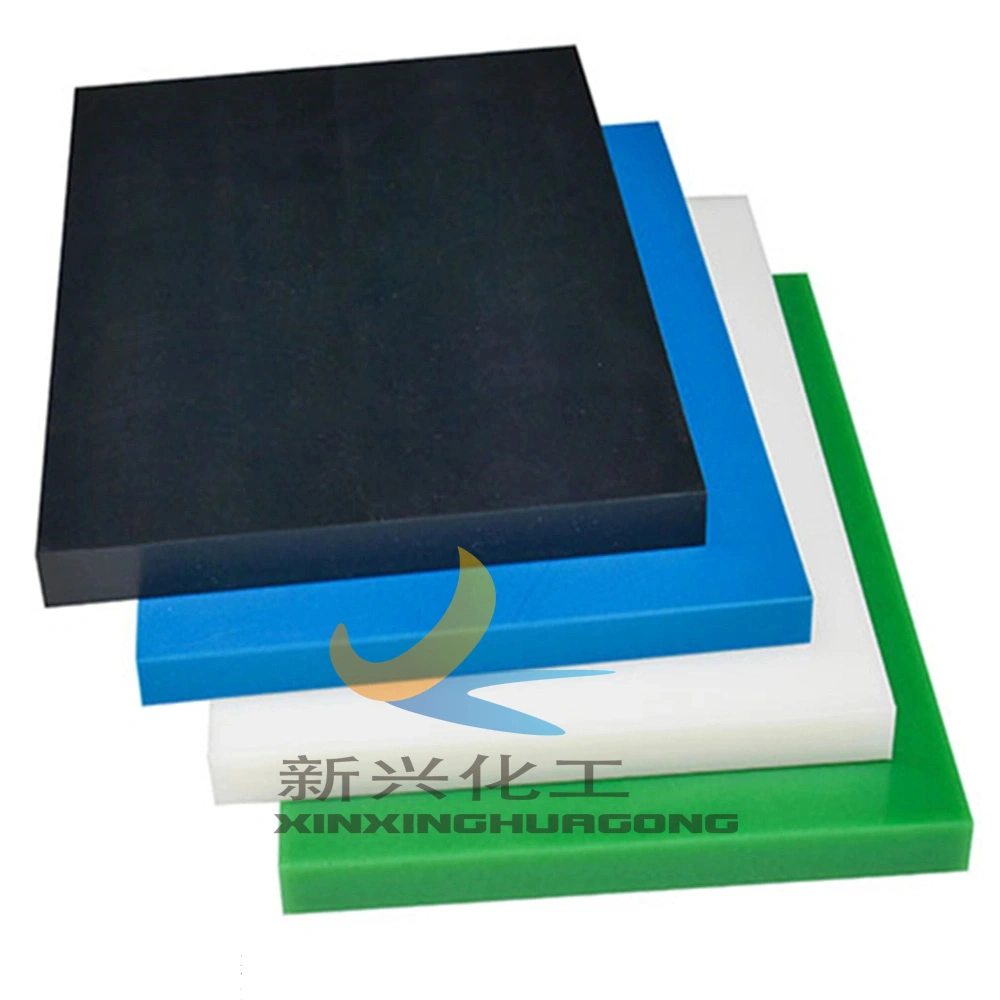

High Wear Resistancepe Sheets, Anti-Corrosion UHMWPE/HDPE Sheets/PE Boards

Brief Introduction UHMWPE(Ultrahigh molecular weight polyethylene) is a thermoplastic engineering material with high mol

Description

Basic Info

| Model NO. | UH7003 |

| Density | 0.93-0.97 |

| Abrasion | 80, Steel = 100 |

| Thickness Tolerance | + 3 mm ( Any Size Can Be Customized by Your Requir |

| Friction Coefficient | 0.12-0.15 |

| Impact Strength | 131mj/mm2 |

| Transport Package | Plywood Pallet |

| Specification | 4520x2000x(6-300)mm |

| Trademark | XINXING |

| Origin | China |

| HS Code | 3920109010 |

| Production Capacity | 500000pieces/Year |

Product Description

Brief Introduction

UHMWPE(Ultrahigh molecular weight polyethylene) is a thermoplastic engineering material with high molecular weight and excellent performance. On the whole, it almost focused on the advantages of all kinds of plastic, which has incomparable wear resistance, impact resistance, self-lubrication, corrosion resistance, low temperature resistance, sanitary nontaxicity, extremely high smoothness and low water absorption. In fact, there is no single polymer material has so many excellent properties like UHMWPE material.

What is HDPE Materials?High density polyethylene (HDPE) is a strong, durable, lightweight, and chemically resistant plastic material popular for a variety of applications. HDPE is easy to fabricate and weld using thermoplastic welding equipment making it an excellent choice for fabricated water tanks and chemical tanks.

Does HDPE perform well outdoors?UV stabilized grade HDPE performs well in outdoor environments where extreme conditions like water and UV exposure are present. UV stabilized HDPE is a popular choice for playgrounds, outdoor cabinetry, and marine construction. Marine grade HDPE is commonly referred to as Seaboard, StarBoard, marine lumber, marine plywood, and XINXING HDPE BoardWhat is the difference between HDPE and LDPE?HDPE has greater strength and stiffness than LDP.What are common HDPE applications?High density polyethylene sheet - HDPE is widely used for chemical tanks, cutting boards for food preparation, water pipe flanges (HDPE pipe grade), outdoor and indoor playground systems, marine construction (pile guards, bumpers, anti-skid surfaces), orthotics and prosthetics, and many more applications.HDPE Standard Sizes, Cut-to-Size, and FabricationHDPE colors- HDPE is available in many colors including natural, black, red, yellow, green, beige, blue, polar white, mercury gray, seafoam, and sandshade. HDPE sheet for O&P is available in natural.

Merits and Properties *High-wear resistance, seven times wear resistance than steel, four times than PTFE

*High anti-impact resistance, two times impact resistance than PC, five times than ABS.

*Good self-lubrication, the same as PTFE, better than steel and brass appended lubricating oil.

*Good anti-corrosion resistance, it has very stable chemicals property and can endure the corrosion of all kinds of corrosive medium and organic solvent in certain rang of temperature and humidity.

*High-inadhesion resistance, the surface of product hardly affixes other materials.

*High-impact resistance, ten times impact resistance than PA66, eight times than PTFE.

*Good low temperature resistance, in liquefied nitrogen (- 196ºC), it still has the prolongation. In fact, few other materials can reach to this performance.

*Non-toxic and clean property, UHMW-PE material that made by Shandong Xinxing Chemical Company, which meets the FDA (Food and Drug Administration) and ASDA (United States Department of Agriculture) permit to apply in food and medicine fields.

Specification Virgin Chemical Resistant PE 1000 UHMWPE Plastic Sheets Properties

Item | Test method | Unit | UHMWPE 1000-V | UHMWPE 1000-DS |

| Density | ISO1183-1 | g/cm3 | 0.93-0.95 | 0.95-0.96 |

| Yield Strength | ASTM D-638 | N/mm2 | 15-22 | 15-22 |

| Breaking Elongation | ISO527 | % | >200% | >100% |

| Impact strength | ISO179 | Kj/m2 | 130-170 | 90-130 |

| Abrasion | ISO15527 | Steel=100 | 80-110 | 110-130 |

| Shore Hardness | ISO 868 | Shore D | 63-64 | 63-67 |

| Friction Coefficient(Static state) | ASTM D-1894 | Unitless | <0.2 | <0.2 |

| Operating temperature | - | ºC | -80 to +80 | -80 to +80 |

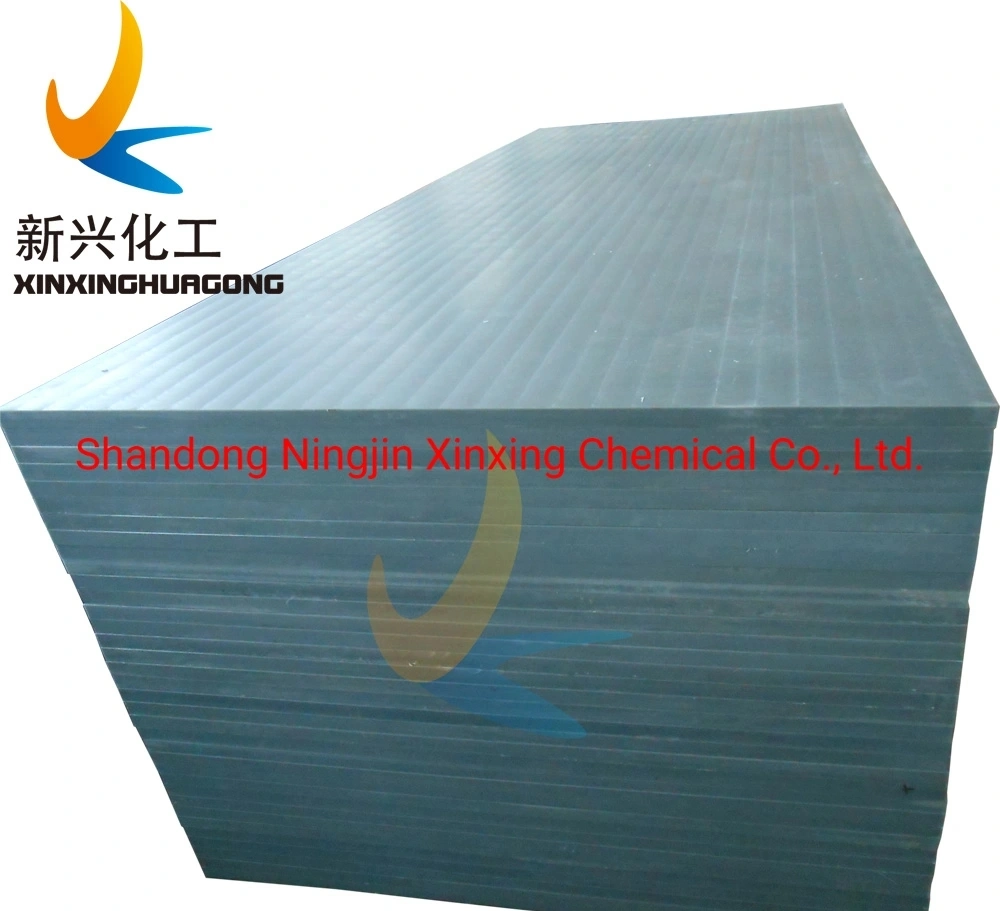

| SIZES |

| 2000x1000x(6-300)mm | 3050x3050x(6-300)mm |

| 5040x1330x(6-300)mm | 4730x1230x(6-300)mm |

| 3050x1220x(6-300)mm | 6050x1820x(6-300)mm |

| 3030x1550x(6-300)mm | 4520x2000x(6-300)mm |

Any size within the standard size is available.

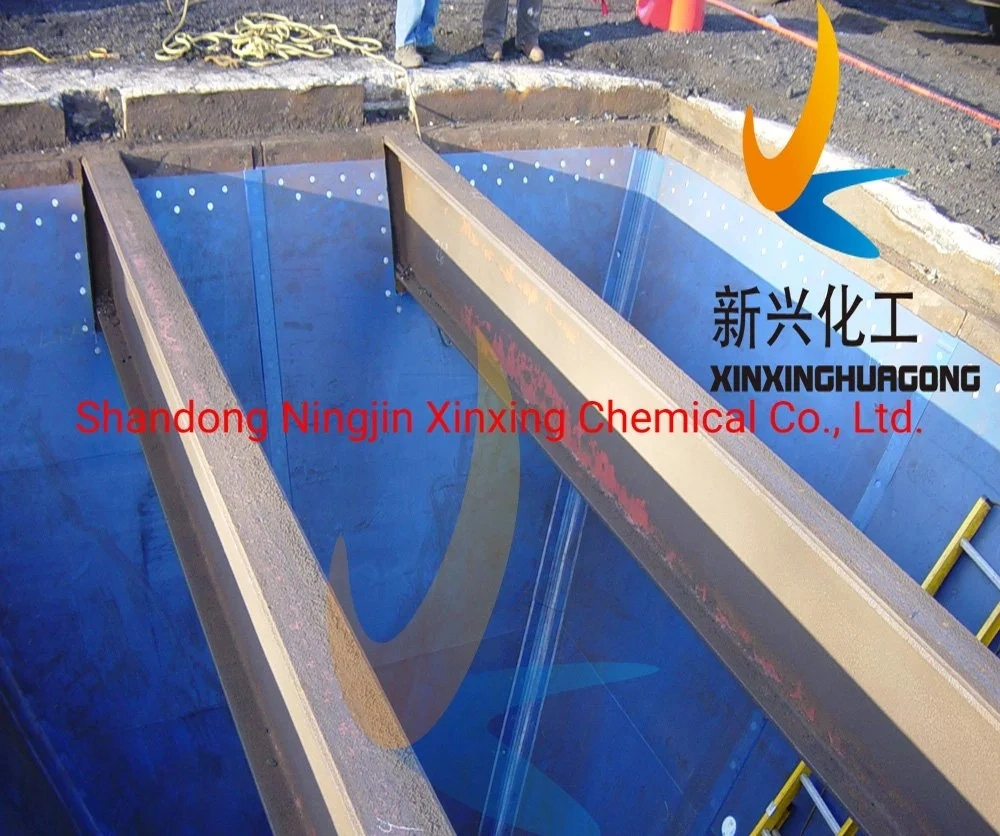

Applications:

UHMWPE/HDPE Sheet for Chute, Hopper and Truck Bed LinersUHMWPE/HDPE Sheet for Wear Strips and Guide RailsUHMWPE/HDPE Sheet for Star Wheels, Sprockets and Conveyor TracksUHMWPE/HDPE Sheet for Bumpers and Marine Dock FendersUHMWPE/HDPE Sheet for Bushings, Bearings and RollersUHMWPE/HDPE Sheet for Jig Stock

About Shandong Ningjin Xinxing Chemical.

With the excellent experience of many years in manufacturing engineering plastics, Xinxing was established in 1989. Now, it becomes the largest and most professional manufacturer of Engineer plastics such as UHMWPE Sheets, ground protection mats, crane outrigger pads, UHMWPE fender pads, wear-resisting liners, HDPE Sheets and parts, PP sheets and parts and other engineer plastics.

Our factory covers an area of 36000 square meters which has 7 big workshops for different products and application. Xinxing is the only manufacturer that produces both extruded and pressed plastic products in China and represents the most advanced productive forces and highest quality.

Our products are widely exported to many countries all over the world such as Indonesia, Malaysia, Korea, Japan, Russia, Germany, India, England, Italy, South America, Canada, Chile, etc.

Our management creed is "Quality first, Customer first, Keeping improving". We are willing to establish a wide and continuous cooperation with enterprises home and abroad. We sincerely hope to establish business relations with you.

We sincerely look forward to establishing business relationship with you. Please contact me if you have any other questions. I would like to help you in time.

Our Contact

Send now