Low Friction Coefficient, High Wear-Resisting Plastic Sheets, Lubricating and Wear-Resisting Polymer Plastic UHMWPE 1000 Wear Liners, Coal Bin Liners

Low Friction Coefficient, High Wear-Resisting Plastic Sheets, Lubricating and Wear-Resisting Polymer Plastic UHMWPE 1000

Description

Basic Info

| Model NO. | XX505 |

| Density | 0.93-0.97 |

| Abrasion | 80, Steel = 100 |

| Friction Coefficient | 0.12-0.15 |

| UV | Anti-Ultra Violet |

| Feature-1 | Wear Resistant |

| Feature-2 | High Impact Resistant |

| Feature-3 | Chemical Resistant |

| Surface | Smooth |

| Transport Package | Plywood Pallet |

| Specification | 3100× 1050× (5-200)MM |

| Trademark | XINXING |

| Origin | China |

| HS Code | 3920109010 |

| Production Capacity | 500000pieces/Year |

Product Description

Low Friction Coefficient, High Wear-Resisting Plastic Sheets, Lubricating and Wear-Resisting Polymer Plastic UHMWPE 1000 Wear Liners, Coal Bin Liners

Brief Introduction

UHMWPE(Ultrahigh molecular weight polyethylene) is a thermoplastic engineering material with high molecular weight and excellent performance.

On the whole, it almost focused on the advantages of all kinds of plastic, which has incomparable wear resistance, impact resistance, self-lubrication, corrosion resistance, low temperature resistance, sanitary nontaxicity, extremely high smoothness and low water absorption. In fact, there is no single polymer material has so many excellent properties like UHMWPE material.

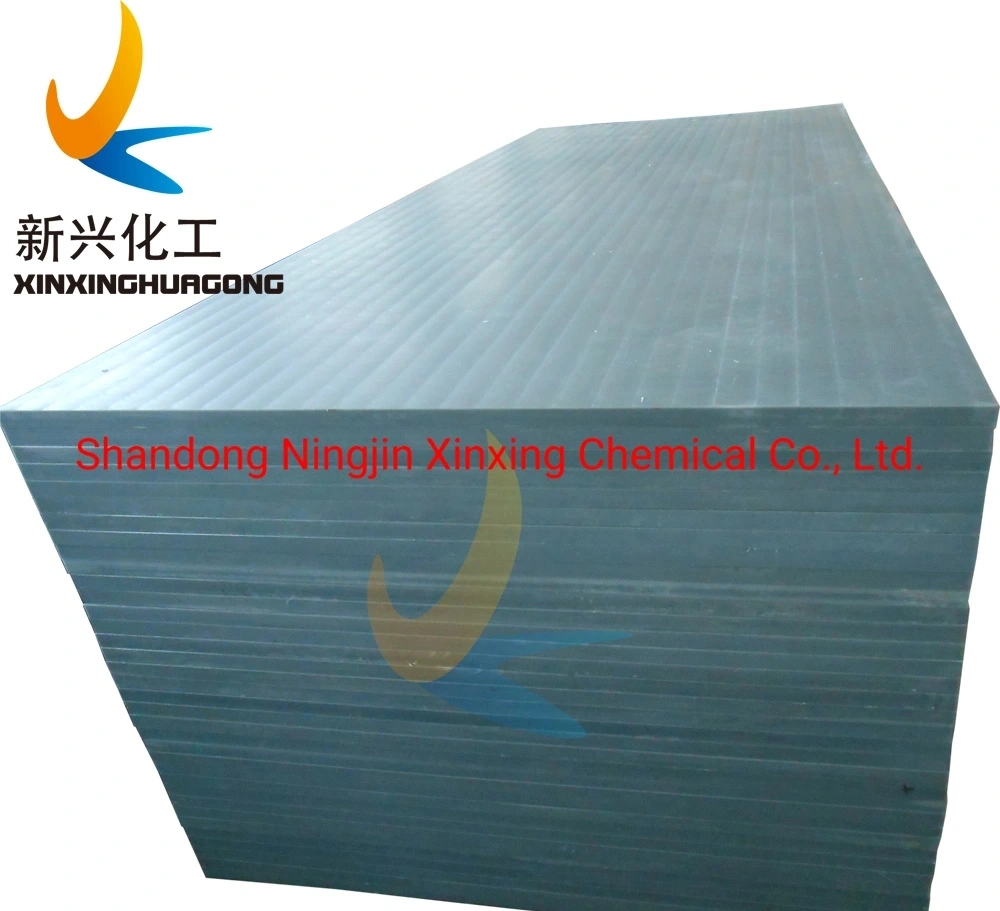

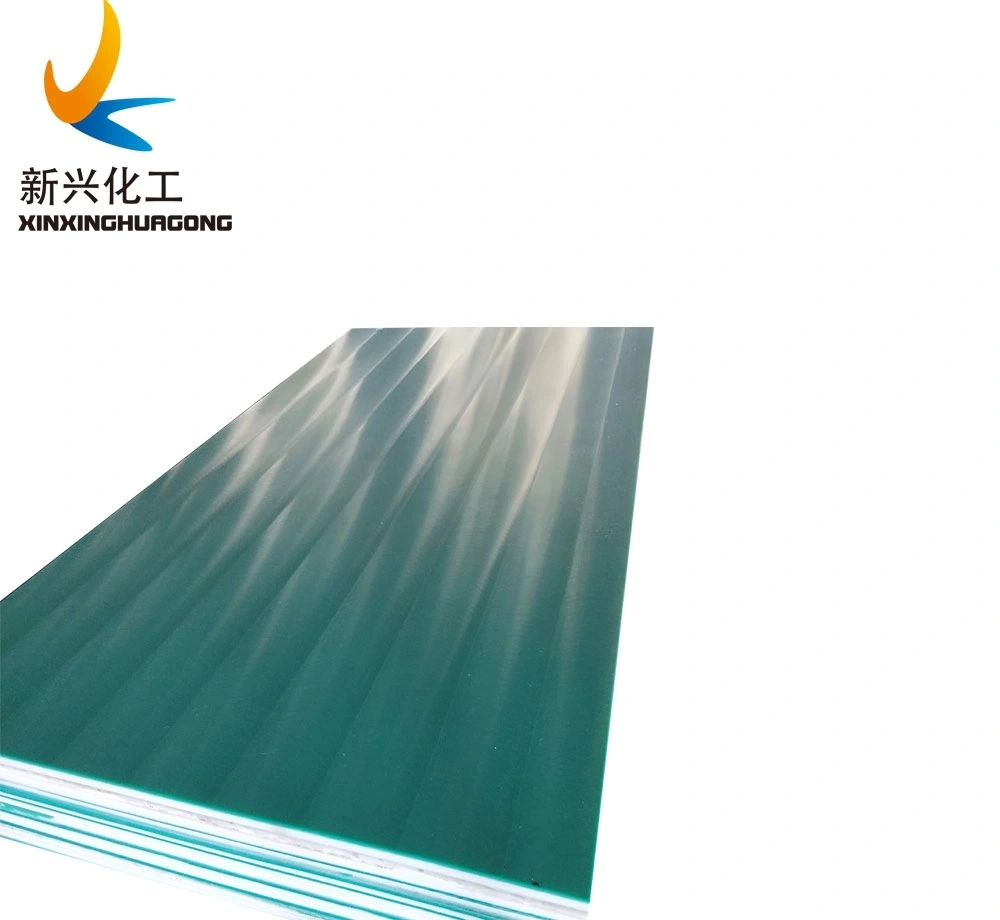

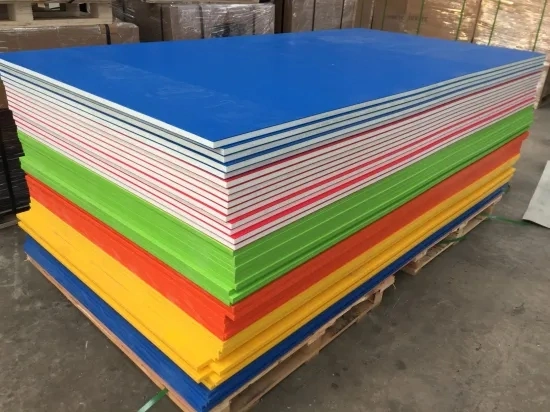

So, we provide UHMWPE liner in various shapes and sizes, which are available in different color such as Black, Grey, Natural, etc.

However, we offer in UHMWPE liner customized designs with distinct specifications in colors and dimensions.

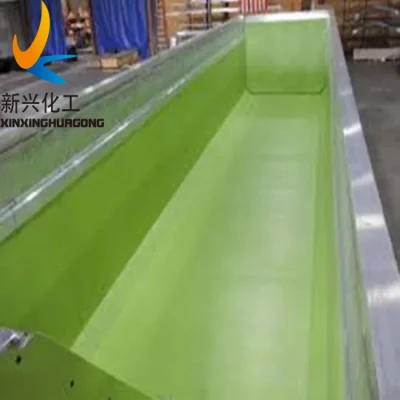

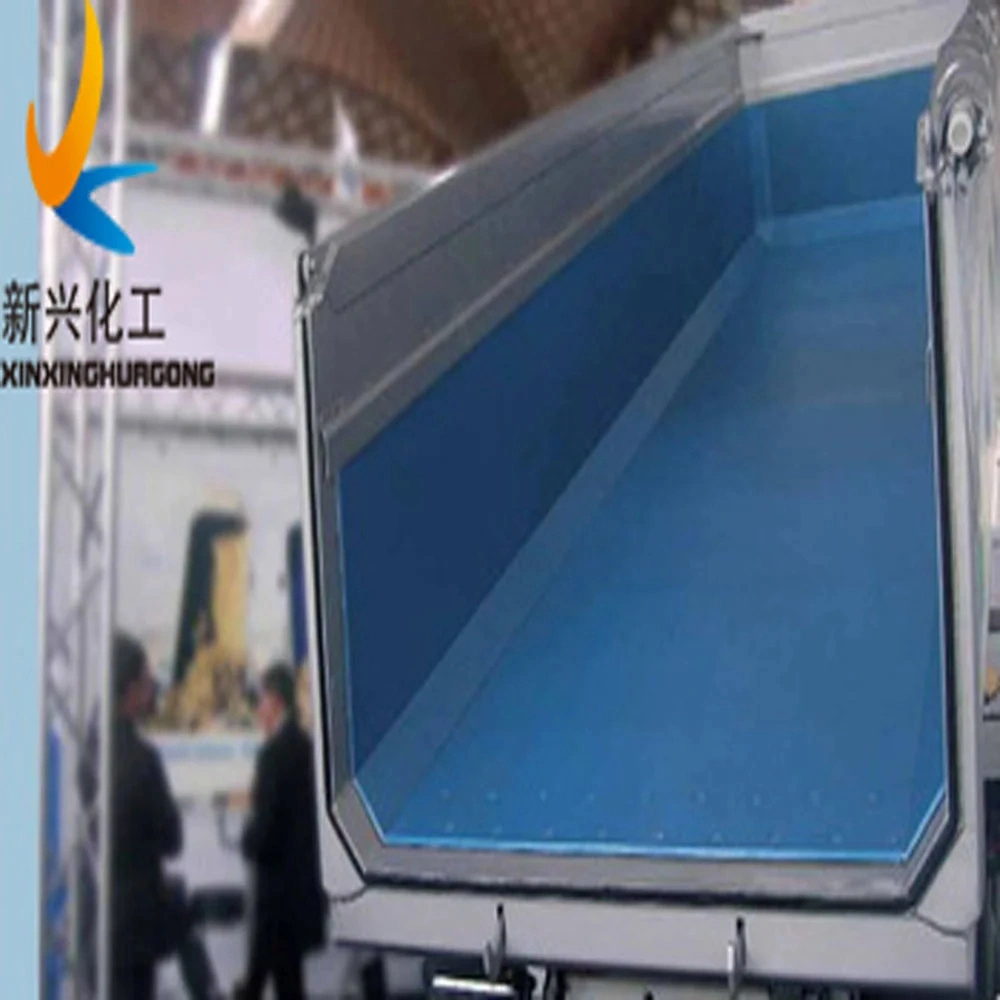

UHMWPE lining sheets assist to reduce typical flow problems of bulk solids in bins, hoppers, chutes, truck beds and other applications. However, every application, brings with it unique challenges and places special demands on the plastic lining materials.

Normal standard size:

| length(mm) | width(mm) | thickness(mm) |

| 2000 | 1000 | 5-300 |

| 2000 | 2000 | 5-300 |

| 2440 | 1220 | 5-200 |

| 3000 | 1500 | 5-200 |

| 3050 | 1220 | 5-200 |

| 3100 | 1050 | 5-200 |

| 3100 | 1500 | 5-200 |

Size also could be customised

Color: Black, White, Blue, Red, Yellow, Green

Excellent Advantages of UHMWPE Liner

| Low dynamic friction coefficient | No incrustations of bulk material |

| Extreme wear resistance | No bridging caused in hoppers |

| Chemical and corrosion resistance | Enhanced protection of plant and machinery against wear |

| Light weight | Faster bulk material flow |

| High anti-impact strength (up to 170KJ/m m2) | Low cost |

Technical Data of UHMWPE liner

| Unit | ASTM test | HDPE | UHMWPE | |

| Tensile strength | Psi | D-638 | 4000 | 3100 |

| Flexural modulus | psi | D-790 | 200000 | 110000 |

| Notched impact | Ft-lbs/in of notch | D-256 | 1.3 | 18 |

| Heat deflection temperature | ºF | D-648 | 172 | - |

| Maximum continuous service temperature in air | ºF | - | 180 | |

| Water absorption | % | D-570 | 0.1 | slight |

| Coefficient of liner thermal expansion | in/in/ºF 10-5 | D-696 | 7.0 | 11.1 |

Application

UHMWPE liner plate can be applied in bunker, stock bin , funnel,chute and etc in the following industries :coal ,metallurgy, steel, thermal power, cement, coking, glass, separation coal and etc.

UHMWPE liner plate can solve the blocking and bonding during production ,high-efficiency

Features:

Meets FDA and USDA guidelines3-A Dairy approved (Natural color)Helps to reduce noiseSelf-lubricatingChemical, corrosion and wear resistantNo moisture absorptionNon-toxic, low-friction surface

About Shandong Ningjin Xinxing Chemical.

With the excellent experience of many years in manufacturing engineering plastics, Xinxing was established in 1989. Now, it becomes the largest and most professional manufacturer of Engineer plastics such as UHMWPE Sheets, ground protection mats, crane outrigger pads, UHMWPE fender pads, wear-resisting liners, HDPE Sheets and parts, PP sheets and parts and other engineer plastics.

Our factory covers an area of 36000 square meters which has 7 big workshops for different products and application. Xinxing is the only manufacturer that produces both extruded and pressed plastic products in China and represents the most advanced productive forces and highest quality.

Our products are widely exported to many countries all over the world such as Indonesia, Malaysia, Korea, Japan, Russia, Germany, India, England, Italy, South America, Canada, Chile, etc.

Our management creed is "Quality first, Customer first, Keeping improving". We are willing to establish a wide and continuous cooperation with enterprises home and abroad. We sincerely hope to establish business relations with you.

We sincerely look forward to establishing business relationship with you. Please contact me if you have any other questions. I would like to help you in time.

Our Contact

Send now